Categories

- Case Studies (12)

- Solutions (4)

- Blog (90)

A large manufacturing enterprise faced challenges in managing personnel in its production workshop. The workshop had a complex layout with frequent personnel movement, and traditional monitoring methods failed to provide real-time insights into employees’ precise locations and behaviors. This resulted in low production efficiency and potential safety risks. To address this issue, the company implemented the “Real-time personnel tracking Edge” solution.

Solution

By deploying the “Real-time personnel tracking Edge” solution, the company achieved the following:

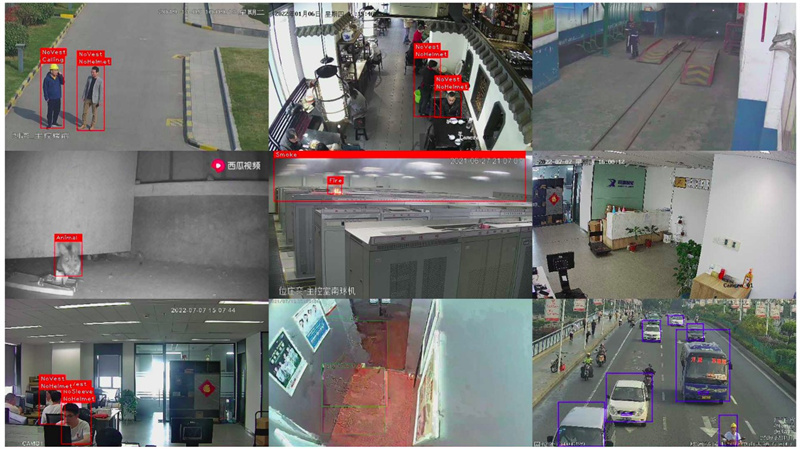

1. Real-time Location Tracking: Precisely recorded the real-time location of every employee in the workshop using edge computing devices.

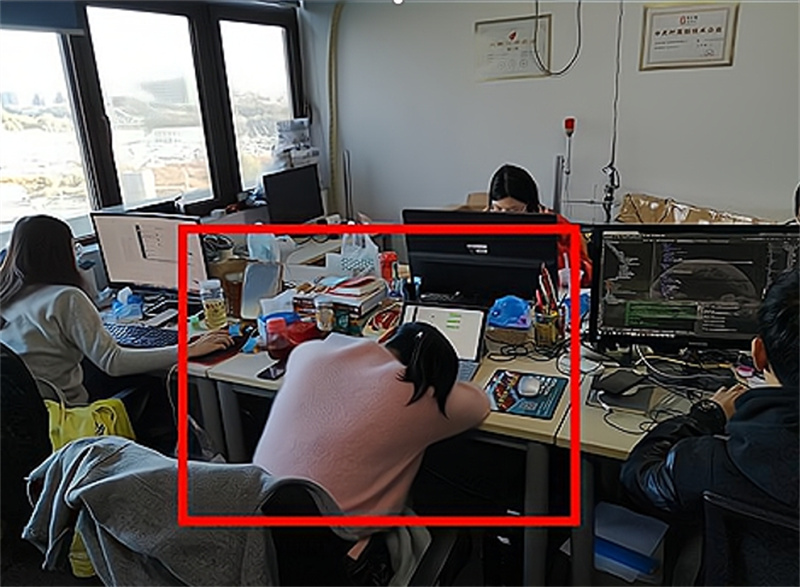

2. Behavior Analysis: Identified abnormal behaviors through intelligent algorithms, such as employees entering restricted areas or lingering in non-work zones for extended periods.

3. Localized Data Processing: All data was processed locally on the device, ensuring privacy and reducing data transmission latency.

4. Efficient Management: Managers could view workshop dynamics in real-time via a visual interface, enabling quick adjustments to production schedules and improving efficiency.

Project Results:

1. Improved Production Efficiency: The real-time tracking feature helped optimize personnel allocation, increasing production efficiency by 25%.

2. Reduced Safety Risks: The behavior analysis function identified and addressed potential safety issues, reducing accident rates by 40%.

3. Transparent Personnel Management: Managers gained real-time insights into employee dynamics, eliminating management blind spots.

4. System Scalability: The device supports algorithm upgrades, allowing for the addition of more functional modules as needed in the future.